Henry Ford didn’t invent the motor car, but his Model T changed the face of our towns, cities and countryside forever.

The affordable American automobile, nicknamed Tin Lizzy, was the first to be mass-produced on an assembly line, and got the rising middle-classes moving in unprecedented numbers.

We look at the story of arguably the most influential car in history.

The honour of inventing the first automobile goes to Germany’s Karl Benz and his Benz Patent Motorwagen, unveiled way back in 1885.

But until Ford’s Model T was launched 23 years later, cars were expensive, often unreliable and produced in only limited numbers. They were, essentially, toys for the rich.

All that was to change thanks to the vision, and determination, of one man, the son of a Dearborn, Michigan farmer who built a steam-powered car in his father’s farm workshop.

Dismissing steam as too dangerous, Ford built his first petrol-powered car in 1892, by which time he was working as an engineer with the Edison Illuminating Company of Detroit, rising to chief engineer in 1893.

Creating the Ford Motor Company

Continuing with his development of the motor car as a side project, Ford created the self-propelled Quadricycle in 1896 and, encouraged by Edison, completed a second vehicle two years later.

He quit his job and formed the Detroit Motor Company in 1899, but this initial foray into the embryonic motor industry proved short lived, the company dissolving in 1901.

Having successfully built and raced a 26hp car in October of that year, the Henry Ford Company was founded in November, backed by lumber baron William H Murphy and other stockholders in the failed earlier enterprise.

Within a year though, Ford had left the company that bore his name after Murphy brought in Henry Leland as a consultant, subsequently changing its name to the Cadillac Automobile Company.

Undeterred, Ford teamed up with Detroit coal dealer Alexander Malcomson with the aim of designing and building an inexpensive car, enlisting John and Horace Dodge to supply parts.

Sales failed to take off, however, and trouble brewed when the Dodge brothers wanted payment.

Malcomson brought in new investors and persuaded the Dodges to take shares in the newly-named Ford Motor Company, inaugurated on June 6, 1903, when Ford himself was 39.

The road to the Model T

In the early years, Ford turned out a few hand-built cars a day at its factories, first at Mack Avenue and later at the purpose-built Piquette Avenue plant, now a museum dubbed the “birthplace of a revolution”, where the first Model T was first made in 1908.

First came models A, B, C, F, K, N, R, and S, which sold only hundreds, or a few thousand, a year.

They were all stepping stones on the path to the car, and the production methods used to build it, that would change motoring, and manufacturing at scale, forever.

Ahead of the Model T’s launch, somewhere between 1903 and 1906, Ford declared that he would “build a motor car for the great multitude”.

“It will be large enough for the family, but small enough for the individual to run and care for,” he said. “It will be constructed of the best materials, by the best men to be hired, after the simplest designs that modern engineering can devise.

“But it will be so low in price that no man making a good salary will be unable to own one – and enjoy with his family the blessing of hours of pleasure in God’s great open spaces.”

He was as good as his word, but even he was probably startled at the success that unfolded over the following two decades, with 16.5million Model Ts eventually rolling off the increasingly sophisticated production lines.

The first Model Ts

The Model T was designed by a team headed by Childe Harold Wills, an engineer and one of the first employees of the Ford Motor Company.

Early models were hand-built, using traditional methods, and only 11 cars were produced in the first month of manufacture.

Power was provided by a 2.9-litre, inline four-cylinder engine with a block cast in one piece, common practice today but unusual at the time.

A removable cylinder head, again not common at the time, made tasks like grinding the valves, which needed to be done frequently, much easier.

The engine produced 20hp, propelling the car to a top speed of between 40 to 45mph, depending on the terrain, and was able to run on either gasoline (petrol), kerosene or ethanol.

A hand crank was used to start the car, with an unusual ignition system utilising a low-voltage magneto in the flywheel supplying alternating current to trembler coils to drive the spark plugs.

There was no battery, with the hand cranking supplying sufficient electricity for starting, and early lighting systems powered by acetylene or oil.

Starting the car was not as simple as it sounds, however.

After clambering underneath to turn on the fuel cock, the motorist climbed into the seat and used the key in the brass ignition switch to close the circuit and set the hand throttle to the left of the steering wheel.

Moving to the front of the car, the driver pulled on the choke, a wire loop sticking through the radiator housing – engaged the crank handle and turned the engine over until it fired.

As long as the engine speed had been set correctly, the mixture was sufficiently rich (adjusted with a brass wheel on the fascia) and the ignition timing set correctly with a lever to the right of the steering wheel, the engine would burst into life. Easy as that!

Driving was nothing like a modern car either, described at the time as trying to pat your head with one hand while circling your stomach with the other.

The planetary gear type transmission, with two forward gears and one reverse, was controlled with three foot pedals, marked C, B and R for clutch, brake and reverse, and a lever mounted next to the driver’s seat.

Early models used a lever to operate reverse, while the brake slowed the transmission rather than the wheels.

To move forward, the driver releases the combined handbrake-clutch neutraliser lever to the mid-way position and, with the hand throttle set in a low enough position for the revs not to jolt the driveline unduly but high enough for the engine not to stall, depresses the left-hand of the three pedals in front of him while balancing the car against the right-hand brake pedal.

Simple!

Fit for the road

One of the most important considerations when designing a car aimed at mass ownership was that it had to be fit for the road conditions at the time.

The world was a very different place to today, with almost all roads outside a handful in the big cities made of dirt, and agriculture the primary occupation of many.

So the design of the car had to account for contemporary realities, of unmade roads and also of how the vehicle would be used.

It was, effectively, the first all-terrain vehicle, intentionally designed as a rugged workhorse with good ground clearance that could cope with muddy farm tracks, snow-bound roads and traverse shallow streams.

The Ford’s off-road abilities were never better demonstrated than in the Ocean to Ocean Automobile Endurance Contest, a race that finished in Seattle on June 23, 1909.

Before the race, Henry Ford predicted that it would “give Americans an opportunity to appreciate the vast possibilities of the motor car”.

The Daily Arizona Silver Belt reported on June 24 that 15,000 people cheered the Model T home in front, blocking the streets around the main entrance to the Alaska-Yukon-Pacific Exposition, a world’s fair held in the city to publicize the development of the Pacific Northwest.

Ford car No. 2, driven by W B Scott, left New York on June 1, and crossed the tape 22 days and 55 minutes later in Seattle.

The newspaper reported that the Ford was “seriously delayed during the last 100 miles by deep snow at Snoqualmie Pass, in the Cascade mountains”.

But the little car, dwarfed by its larger, more powerful competitors, soldiered on through five foot deep snow drifts, as well as axle deep mud and quicksand, to cross the line first.

The car’s ruggedness leant itself for use far beyond that of a road car, with some owners and aftermarket companies converting them into tractors, or hacking them apart and using the engines to power ice saws and other machinery like threshers, balers or generators.

Later, the engines would be used to power home-built aircraft and boats, while many cars were converted into fire trucks and so-called “snowflyers”, with the front wheels replaced by skis.

The Model T was built with a variety of body styles, including a five-passenger touring car, three-passenger roadster, three-passenger open runabout, two-seater coupe and six-seater town car.

Ford famously said that customers could have any colour car they liked, as long as it was black.

Initially, however, the cars were only available in grey, red and green, and by 1912 all cars were painted a midnight blue.

It was only after 1914 that black became the only colour available, a decision thought to be linked to its lower cost, durability and faster drying time.

A surefire winner

Ford dealers were convinced the new car would be a winner, one writing to Henry Ford in response to the car’s official announcement, saying: “It is without doubt the greatest creation in automobiles ever placed before a people and it means that this circular alone will flood your factory with orders.”

Sure enough, dealers were inundated with orders, with 15,000 placed before a single car had been manufactured, the asking price a comparatively modest $825, rising to $850 for the touring model.

Scores of newspapers across the US reported the mere ownership of a Model T, such as the article in The Leavenworth Echo of December 11, 1908, which noted “the lucky recipients”, J C Lilly, W B Paton, F T Spiller and Grant Paton, “each buying one of the new popular Ford Model ‘T’ touring cars”.

Like our illustration of the Ford Model T at the beginning of the article?

Download a free high-quality poster version here.

Journeys that would be routine and mundane only a few years later were considered newsworthy, like Dr William C Sparks who, in August 1909, according to the The Sunday Star, of Washington DC, “left Tuesday last for Boston, Mass., in his Model T Ford touring car, accompanied by his wife. They will visit relatives in the suburbs of Boston.”

Maybe the modern equivalent would be you visiting your nan in a fully autonomous car.

The motor car was slowly but surely beginning to replace the horse and carriage, as reported by The Baraboo News, of Wisconsin, in May 1909, when ex-master mechanic W F Hufman decided he “would rather have an automobile than the fine horse which he drives”.

“For many months he has been inspecting the different makes of machines and has decided that he wants a Model T Ford touring car,” the newspaper noted. “The machine fully equipped has been ordered to arrive in June.”

In March 1909, the Model T again proved itself capable of hitherto implausible feats of motoring endurance, when Charles C Caton and party set out to drive the 66 mountainous miles between Santa Fe and Las Vegas, New Mexico.

The Santa Fe New Mexican told of the “remarkable trip”, at four hours and 40 minutes driving time, a record between the two cities.

“The time is remarkable, considering the terrible piece of road between Canoncita and Glorieta and the impassibility of Tecolote Hill,” it wrote.

“The return trip was more eventful. The run from Las Vega to Fulton was made between 4.30pm and 7pm, in a blinding snowstorm, during which the party lost every vestige of the road and ploughed across country the distance of 36 miles.”

Who needs a Land Rover…?

Mass production and the global car

At the beginning of May 1909, demand was so great that Ford stopped taking orders for more than two months.

Henry was selling every car he could make, but he wanted to make every car he could sell, an aim that would only come about with the move to assembly line production.

Although credit for the creation of the assembly line lies with Ransom E Olds and production of the Oldsmobile Curved Dash in 1901, it was Ford and his engineers who refined and expanded the process over time.

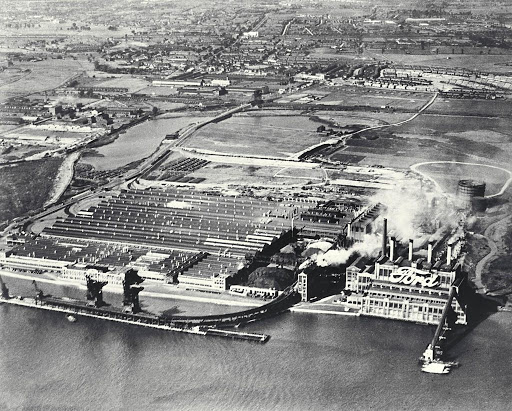

Demand soon outstripped capacity at the Piquette Avenue plant, and a vast new production facility, the Highland Park Complex, was built just north of the Detroit border.

The best minds at Ford were dedicated to producing a system that would dramatically increase production, as a result lowering the cost of the car to customers.

The assembly line soon sped up production to three cars per minute, reducing the time taken to build each car from 12 and a half hours to just 93 minutes, with less manpower required.

Ford later described assembly line mass production as “craftsmanship with the drudgery taken out of it”.

By 1914, Ford produced more cars than all other manufacturers combined, and at one point half of all cars on the road in the world were Fords.

Over time, Ford was able to fine-tune the production process, with scale also slashing overheads per car.

By 1925, the cost of a Runabout model had reduced from $825 to just $260.

The Model T was the first car to be built simultaneously in countries all over the world, with plants in England and Canada followed by assembly in Germany, Argentina, France, Spain, Brazil and Mexico to name a few.

The only continent without a Model T assembly plant was Antarctica.

Ford in the UK

Just three years after the Model T was launched in the US, the first UK factory was opened at the Trafford Park Assembly Plant, a disused tramcar carriage works beside the Manchester Ship Canal.

In the early days it merely assembled parts sent over from Dearborn, but supply chain issues quickly saw the plant acquire parts from closer to home, with entire bodies built by local body builders Scott Brothers and delivered to Trafford Park for final assembly.

Once the assembly line production method was up and running in Detroit, it was quickly transferred to Manchester, output doubling between 1912 and 1913 from 3,000 to 6,000 cars a year.

Chassis were placed on a powered track, which moved it along to a series of stations where men would add a single component before it reached the end of the line fully assembled.

There it would be attached to a pre-assembled and fully trimmed body.

It was Britain’s first moving assembly line.

British-built Model Ts were priced at £175 in 1912, £65 cheaper than the slower, smaller Austin 10hp

Ford was already well-placed to thrive in the UK thanks to the efforts of first Aubrey Blakiston, the company’s first British agency, and entrepreneur Percival Perry, who joined Blakiston in 1905 and became managing director of the Central Motor Company the following year.

Perry suffered regularly from shortage of credit as Henry Ford insisted on full payment on cars when they were loaded for export at New York Harbour, but over time he struck up a good relationship with the American.

This reaped huge dividends in 1909, when Ford contacted Perry in 1909 to manage a Ford branch company for Britain.

Perry set up a network of Ford dealers, and was personally selling more than 400 cars per year imported from the US at his premises in London’s upmarket Shaftesbury Avenue.

He acquired the Trafford Park plant, and was in charge of operations throughout the war, when the factory was placed under government control, producing munitions alongside cars, trucks and ambulances.

More than 30,000 Model Ts were supplied to the military.

Perry left the company in 1919, when tensions over policy decisions and his unpaid work to support Britain’s war effort, at odds with Henry Ford’s pacifist stance, boiled over.

By then, 41 per cent of all cars registered in Britain were Fords.

Ford of America imported managers from Detroit to run the UK operations, who identified a new site at Dagenham in Essex in 1923 to ultimately replace the Manchester plant, which was struggling with capacity.

Three years before the Dagenham plant became operational in 1931, and with the US management team having been largely unsuccessful, Ford reversed his decision and appointed Perry as chairman of a new Ford Motor Company Limited, 60 per cent owned by Dearborn.

Model T and the war

Henry Ford’s approach to the first world war was initially very different to Perry’s.

A staunch pacifist, and a prominent supporter of the ‘Keep America Out of the War’ movement, he refused to involve himself or his company in building specialised vehicles for military use, but he did sell Model T rolling chassis and parts to countries involved in the war.

When the US entered the war in 1917, however, he knew he must supply whatever his country needed, manufacturing 390,000 Model Ts to the US military, of which 15,000 were pressed into service with US forces in Europe.

Many were converted into ambulances, and proved particularly adept at traversing rough terrain, as well as light enough to be lifted out of trouble by soldiers if they did become stuck.

Among those who drove Model T ambulances during the war were Walt Disney and Ernest Hemingway.

William Seabrook, an American who drove a Model T ambulance in France, wrote: “Our Fords could go over shell-pitted roads and torn terrain at 30 miles per hour”.

“The ambulance driver works over, under and upon it,” he added. “He paints it and oils it and knows every bolt and nut, its every whim and fancy.”

Allied Forces across Europe, Africa and the Middle East used Model Ts in a variety of configurations, including an early version of the armoured car, half-track and full-track conversions, delivery trucks and personnel carriers.

Although less well-known for its war efforts than the Jeep of the second world war, the Model T carried out a similar role remarkably successfully.

Like our illustration of the Ford Model T at the beginning of the article?

Download a free high-quality poster version here.

Commitment to service and staff

Henry Ford wasn’t just a motoring and manufacturing visionary – he was also wedded to the fair treatment of staff and of providing a total service to his customers.

He is reported to have said: “In the Ford Motor Company we emphasise service equally with sales.”

In June 1910, the San Francisco Call newspaper marvelled at the parts availability for the Model T, with stock held at Ford’s New York branch enough to build 40 complete cars.

William Hughson, of the Standard Motor Car Company, said: “It is a comfortable feeling to know that if a car meets with an accident or a part is lost or broken it can be replaced in as short a time as it takes to send a telegram and have the desired part shipped by express, with no laying up of a car for a long time while a part is being made.”

This made the car especially popular with medical professionals, and others who had come to rely on their cars.

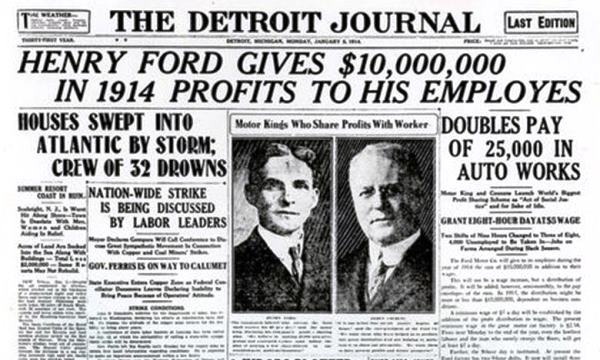

Ford’s approach to management and the treatment of staff was as groundbreaking as his cars, introducing a $5 minimum wage for male factory workers for an eight-hour day in 1914, increased from $2.34 for nine hours. Female workers achieved parity in 1916.

It was more than double the industry average, and proved to be a stroke of genius, increasing assembly line productivity and building a sense of loyalty among the company’s growing workforce, which was up to 16,000 in 1914.

It was, in effect, also a profit-sharing scheme, as reported in The Detroit Journal.

Writing in Ford News, he said: “No one loses anything by raising wages as soon as he is able. It has always paid us. Low wages are the most costly any employer can pay. It is like using low-grade material – the waste makes it very expensive in the end.

“There is no economy in cheap labor or cheap material.”

An article in The Tacoma Times on January 10, 1914, noted that Ford himself was earning an estimated $100 a minute, “except John D Rockefeller…the biggest income of any man in the world”.

Despite this, he was down to earth and keen to pass on the benefits of success to his workforce.

“He’s just as likely as not to come into my office, pound me on the back and begin a wrestling match, before he talks business,” said one of his salesmen.

Ford went further in 1926, becoming one of the first companies in the US to introduce the five-day, 40-hour week, reduced from six days.

Speaking to the New York Times, Henry’s son Edsel, by now company president, said: “Every man needs more than one day a week for rest and recreation.

“The Ford Company always has sought to promote [an] ideal home life for its employees. We believe that in order to live properly every man should have more time to spend with his family.”

Henry added: “It is high time to rid ourselves of the notion that leisure for workmen is either ‘lost time’ or a class privilege.”

He further told Ford News of October 15, 1926, that “the country is ready for the five-day week. It is bound to come through all industry”.

“Just as the eight-hour day opened our way to prosperity in America, so the five-day week will open our way to still greater prosperity.

“Instead of business being slowed up because people are ‘off work’, it will be speeded up because people consume more in their leisure than in their working time. This will lead to more work, and this to more wages.”

Manufacturers all over the country, and the world, soon followed Ford’s lead, and the Monday to Friday working week became standard practice.

A victim of its own success

Henry Ford’s approach to the Model T was very much to get it right, and keep it the same – a credo echoed decades later by the likes of the VW Beetle, Mini and 2CV.

You could hardly blame him, with such a runaway success on his hands.

By the time Ford made its 10millionth car, half of all cars on the road had come from Detroit or the company’s factories around the world.

At peak production, cars were being made at a rate of 2million a year.

But in many ways it was a victim of its own success, as its growth led to a rapid improvement in road surfaces across the world, blunting the need for its ruggedness.

Competitors began to offer vehicles that could take advantage of these better roads, with more power, more comfort, better styling and more choice of colours.

Although there were some styling changes to the Model T over the years, underneath the car remained very similar at its demise in 1927 as it had in 1908.

It gradually lost market share and had become barely profitable by the time Henry and his son Edsel drove the 15millionth Model T out of the factory on May 26, 2027, the car’s official last day of production at its home factory, to be replaced by the new Model A.

The Model T had pioneered mass production, was the first truly affordable automobile, and the first global car.

It sparked a motoring revolution, served the world with distinction in wartime, and later carried thousands of Dust Bowl migrants who travelled the 1,500 miles from Oklahoma to California along Route 66 in the 1930s.

It’s no exaggeration to say it changed the world.